Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin

Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin Detail:

Product Profile

Hardener 2251 is designed for epoxy resin and it is for heating operation under low temperature.

Technical indicator

|

Technical index |

Data |

|

Viscosity (25℃) |

50-100 |

|

Proportion (25℃) |

0.95 |

|

Amine value (mgKOH/g) |

300 |

|

Active hydrogen equivalent |

87 |

|

Gelation time (25℃/100g)minutes |

75 |

|

Film hardening time (25℃) hours |

6 |

|

Complete hardening time (70/25℃) hours |

18 |

Advantage

■ Low viscosity

■ High glossy

■ Long operation time

■ High mechanical strength

Mechanical property

| Mechanical property | Curing process | |

| Tensile strength | 60.5Mpa | 8hours fully cured at 50-60℃ |

| Bending strength | 96.6Mpa | 5hours fully cured at 70-80℃ |

| Bending failure load | 272N | |

| Tensile failure load | 2702N | |

Product Application

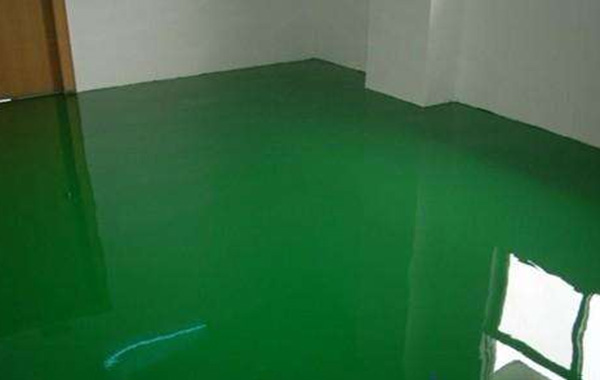

Epoxy floor artesian plane coating/casting material

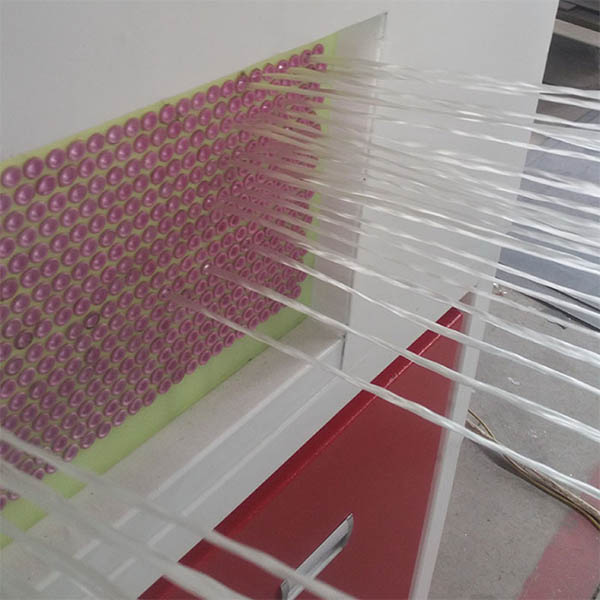

FRP water softening tank production(winding technology)

Product detail pictures:

Related Product Guide:

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin, The product will supply to all over the world, such as: Iraq, Paris, New Zealand, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.