Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin

Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin Detail:

Product Profile

Hardener 2251 is designed for epoxy resin and it is for heating operation under low temperature.

Technical indicator

|

Technical index |

Data |

|

Viscosity (25℃) |

50-100 |

|

Proportion (25℃) |

0.95 |

|

Amine value (mgKOH/g) |

300 |

|

Active hydrogen equivalent |

87 |

|

Gelation time (25℃/100g)minutes |

75 |

|

Film hardening time (25℃) hours |

6 |

|

Complete hardening time (70/25℃) hours |

18 |

Advantage

■ Low viscosity

■ High glossy

■ Long operation time

■ High mechanical strength

Mechanical property

| Mechanical property | Curing process | |

| Tensile strength | 60.5Mpa | 8hours fully cured at 50-60℃ |

| Bending strength | 96.6Mpa | 5hours fully cured at 70-80℃ |

| Bending failure load | 272N | |

| Tensile failure load | 2702N | |

Product Application

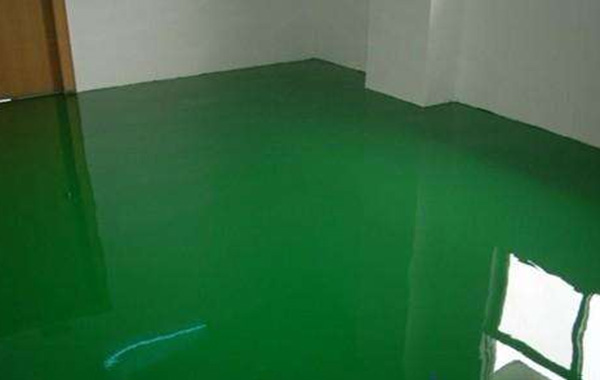

Epoxy floor artesian plane coating/casting material

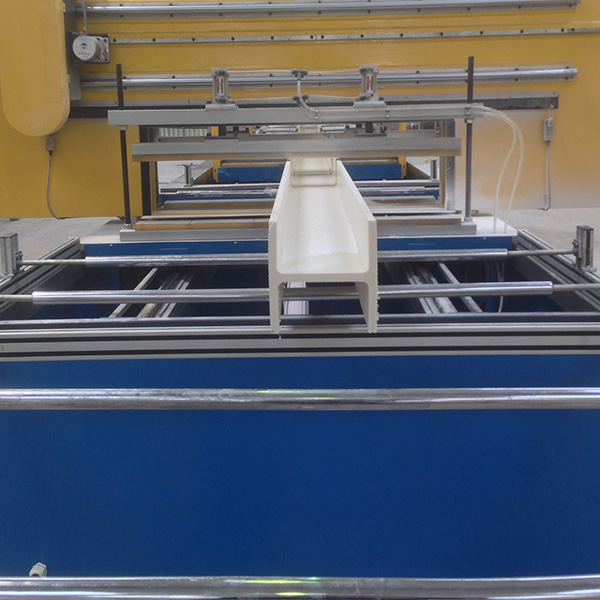

FRP water softening tank production(winding technology)

Product detail pictures:

Related Product Guide:

Bear "Customer initially, High-quality first" in mind, we work closely with our prospects and supply them with efficient and specialist companies for Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin, The product will supply to all over the world, such as: Vietnam, Brasilia, Surabaya, We're introduced as a one of the growing manufacture supplier and export of our merchandise. Now we have a team of dedicated trained experienced who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.