OEM manufacturer Frp Rebar Basalt Rebar - Basalt direct roving – Huabin

OEM manufacturer Frp Rebar Basalt Rebar - Basalt direct roving – Huabin Detail:

Product Profile

Basalt direct roving

Basalt assembled roving

Basalt direct roving is a continuous single-end strand produced pass through the bushing.

Basalt assembled roving consist of several single-end strand assembled together by special assembled machine.

Basalt direct roving can directly used in some industrial application, like textiles fabric, geogrid, woven thermal insulation tape/rope or pultrusion field. But some industrial application asks higher tex and external unwinding, that’s need basalt assembled roving.

Comparing to E-glass fiber and S-glass fiber, or even carbon fiber, basalt fiber has more natural performance advantages:

Thermophysical Properties

| Using temperature / ℃ | -260 – 700 |

| Sintering temperature / ℃ | 1050 |

| Thermal conductivity / W/m.k | 0.03 – 0.038 |

| Strength retention after heat treatment | |

| 20℃ | 100 |

| 200℃ | 95 |

| 400℃ | 82 |

Chemical Properties – Weightlessness

| 3-hour boiling in 2N HC1 | 2.20% |

| 3-hour boiling in 2N NaOH | 6.00% |

| 3-hour boiling in H2O | 0.20% |

Moreover, basalt fiber roving has excellent mechanical and chemical performance as following technical:

■ High frost temperature resistance, high temperature resistance

■ Excellent thermal insulation

■ Corrosion and chemical resistance to alkali and resistance to salty sea water

■ Sound adsorption

■ Electric insulation

■ High tension strength and stiffness

■ Environmental friendly to soil, air and human

Product Application

In view of its excellent performance, basalt fiber roving can use in various fields:

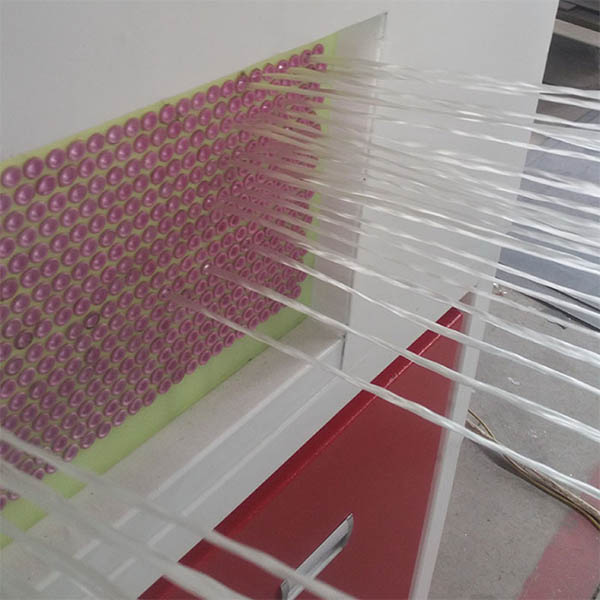

Spray application

Pultrusion bar

Geogrid production

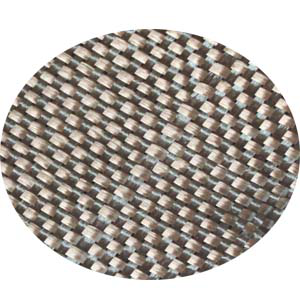

Basalt fabric

Pultrusion profiles

Car parts

High pressure vessel (winding)

Product Specification

|

Monofilament diameter / um |

9-24 |

|

Linear density / tex |

200-4800 |

|

Sizing type |

Silane base |

|

Sizing content / % |

≥0.4 |

|

Moisture content / % |

≤0.2 |

|

Resin compatibility |

Epoxy, vinyl ester, polyester resin, PP, PE, PA |

Product detail pictures:

Related Product Guide:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for OEM manufacturer Frp Rebar Basalt Rebar - Basalt direct roving – Huabin, The product will supply to all over the world, such as: Ghana, Montreal, Peru, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.