A new 4 axis filament winding machine was recently completed!!!

Last year, a Russian client contacted us and required to buy a production line for FRP water treatment tank production.

After we analyze the actual needs of customers, according to the characteristics of the soft water tank and production characteristics, we provided a full set of highly automated production equipment solutions, provided one-stop service, which help client to save purchasing time. The complete production equipment includes liner treatment equipment, highly automatic filament winding equipment, automatic heating equipment and assembly equipment. Now the filament winding machine was completed production.

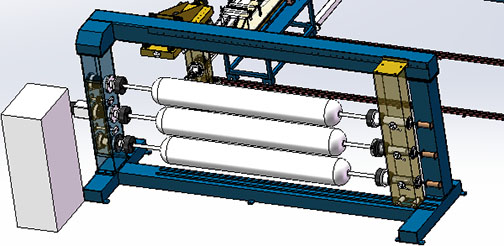

This 4 axis filament winding machine is advanced in domestic field.

1. Gantry structure design.

The winding carriage is designed at one side of the gantry structure, equipped with high precision linear guide and sliding blocks, which provide guarantee of the equipment stable running and high winding accuracy.

2. 3 spindle design.

–3 spindle production can up to DN450mm.

–Maximum tank can up to DN1500mm.

The machine provide guarantee for continuous batch production.

3. High production speed.

4. Equipped with winding software, as long as the operator input the mandrel parameters, the software can automatically calculate winding angle and recommend winding position. Easy operation and highly winding accuracy.

5. Electrical components use Japan Yaskawa motor and driver, which provide stable energy for machine running.

This 4 axis filament winding machine not only produces FRP water treatment tanks, but also used to produce FRP membrane housing and small taper mandrel.

Whether you need a filament winding machine urgently or you are interested in it, welcome to contact us, we are ready to provide customized equipment solution and service to you no matter where you are.

Kindly don’t hesitate to send your requirements to Anna, email: sales10@hbgmec.cn or whatsapp: +86 13180082933.

Post time: Feb-25-2021