Carbon fiber hydrogen storage tank racetracks are on the rise

Source: Jinou New Material Research Institute 2024-02-01

Since March 2022, the National Development and Reform Commission and the National Energy Administration jointly issued the "Medium and Long-Term Plan for the Development of Hydrogen Industry (2021-2035)", the attention of the domestic hydrogen industry has continued to increase, and more than 10 large enterprises have begun to invest money to start the research and development of type III and (or) type IV large-capacity hydrogen storage bottles.

Especially since the end of 2023, major enterprises at home and abroad have made great progress, and more carbon fiber material companies have invested in the layout of carbon fiber hydrogen storage bottles.

(1) The Type IV 700bar high pressure hydrogen storage cylinder -Carbon4 Tank, with a capacity of 350L, developed by German Voith Composites in collaboration with Swiss Huntsman Advanced Materials Co., Ltd. and Toray Carbon Fiber Europe Co., Ltd. was successfully shortlisted for the JEC Composites Innovation Award.

(2) On January 16, part of the production line of the project "Compressed hydrogen aluminum inner bladder carbon fiber fully wound gas cylinder project" (Type III bottle) raised by Changchun Zhiyuan New Energy Equipment Co., Ltd. is being accepted. According to the notice previously issued by the company, the construction period of the construction of the annual output of 30,000 compressed hydrogen carbon fiber fully wound gas cylinder production line is 2 years, and it is expected to reach production in 2026.

(3) On January 23, Biou Laneng four type hydrogen storage bottle mass production plant started in Anting Town. The plant is located in the Jiading Hydrogen Energy Port area and will start production in 2026. By then, up to 60,000 high-pressure hydrogen storage bottles can be produced annually for the Chinese commercial vehicle market.

(4) On December 28, Weihai Guangwei Composite Materials Co., Ltd. announced that it had invested in Cotek (Shandong) Special Equipment Technology Co., LTD., which is the new main body of hydrogen cylinders and peripheral products and systems as the target products, and the carbon fiber used is mainly T700S/800S level, which is mainly provided by Weihai headquarters in the early stage.

(5) In December 2023, the main structure of the third phase of Auseng Technology project was capped in Wujiang, Suzhou. "Aosheng Technology Phase III project layout hydrogen energy vehicle carbon fiber composite products research and development and production, the project based on large volume hydrogen storage bottles, the goal of promoting large heavy trucks, logistics vehicles and other low-cost, clean transportation." The project plans to build an automated production line with an annual output of 100,000 hydrogen storage bottles, and the new output value is expected to exceed 2 billion yuan." Xu Wenqian said that this is the company's new practice in green energy technology, breaking through the carbon fiber winding hydrogen storage bottle "stuck neck" problem, will continue to build a new growth engine in the field of carbon fiber this new material.

With the type IV bottle quietly entering the market, it can be said that it quickly attracted the attention of many hydrogen energy companies. Major enterprises have increased efforts to layout the development and production of type IV bottles, but also triggered widespread concern and hot discussion in the industry, there is a feeling of smoke everywhere.

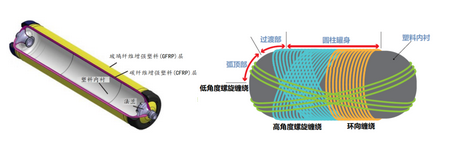

The key technology of carbon fiber composite hydrogen storage bottle

The development of composite high-pressure gas storage cylinder began in the 1950s, and the gas storage cylinder has the characteristics of light weight, high strength, high modulus and strong designability, and is widely used in aerospace, construction, automobiles, rockets and other important fields. In the early days, the formation of composite high-pressure gas cylinders was mainly impregnated resins such as glass fiber and arnylon fiber wrapped layer by layer on aluminum or steel liners, and new materials began to appear in the 1960s, namely boron fiber and carbon fiber reinforced composite materials. At present, the commercialized high-pressure hydrogen storage cylinder is composed of metal steel, and the type II cylinder is mainly made of metal, but the outer layer has been wrapped with glass fiber composite material. Type III and type IV bottles are mainly based on carbon fiber reinforced plastic materials, the former inner liner is metal, the latter inner liner is plastic, and the outside is wound by carbon fiber reinforced plastic, which mainly contains four key technologies.

Most of the carbon fiber composite materials used in hydrogen storage bottles are T700 and above carbon fiber raw materials, which are high-performance carbon fibers and have high industry barriers. However, with the major domestic carbon fiber material companies have broken through the production of carbon fiber prefilament above T800 and capacity expansion, the output of carbon fiber hydrogen storage bottles will usher in a new trend.

Post time: May-24-2024