Manufacturing Companies for Basalt Insulation Sleeving - Basalt fiber rebar – Huabin

Manufacturing Companies for Basalt Insulation Sleeving - Basalt fiber rebar – Huabin Detail:

Product Profile

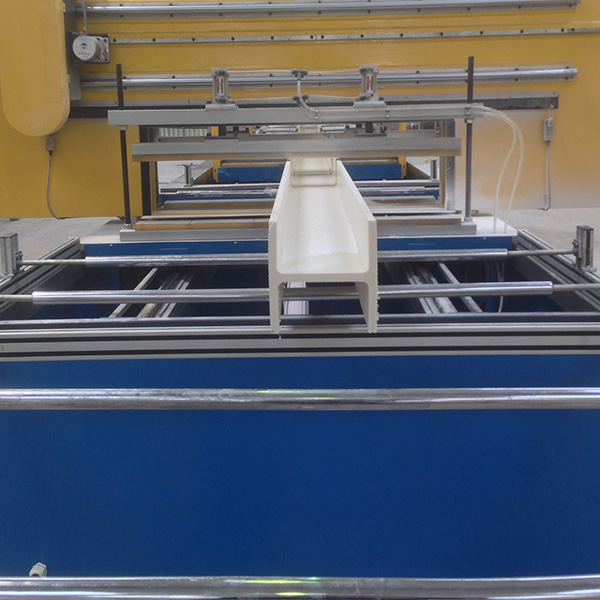

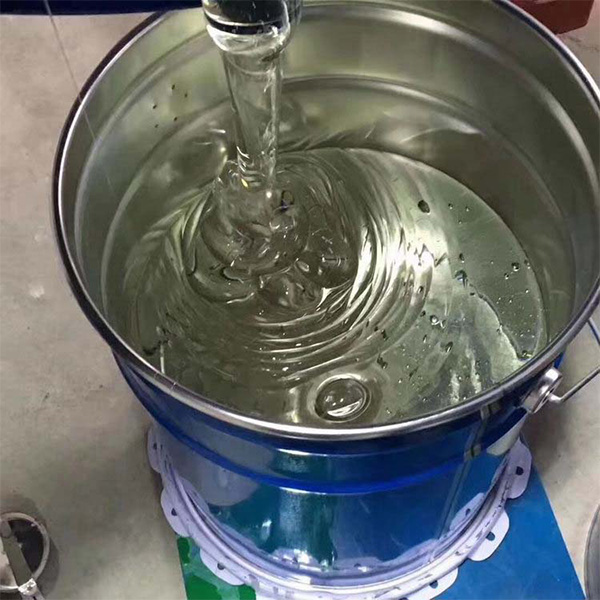

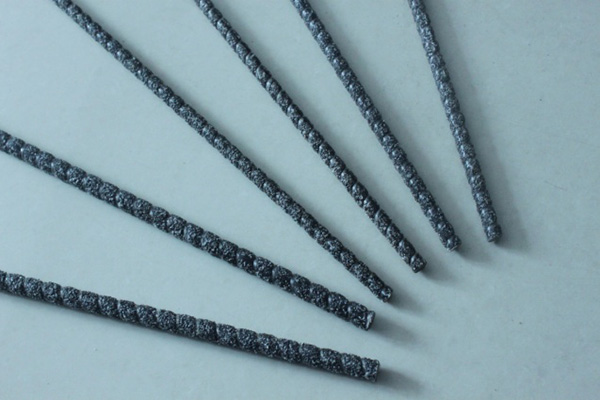

Basalt fiber rebar is formed by pultrusion technology of fiber impregnated resin. The surface of basalt fiber rebar is thread and coated with quartz sand to increase the friction between basalt fibers rebar and the reinforcing medium.

Depend on different resins impregnation, the basalt fiber rebar is divided into:

1. Epoxy resin base basalt fiber rebar

2. Polyester resin base basalt fiber rebar

3. Vinyl ester resin base basalt fiber rebar

Basalt fiber rebar coated different resin, has different tensile strength and used in different environment.

Product Advantages

Due to its raw material - continuous basalt fiber, thus basalt fiber rebar shows perfect properties:

■ Low weight: only 1/4 of the weight of steel rebar based on same diameter.

■ High tension strength: almost 3 times of the strength of steel rebar based on same diameter.

■ Lower thermal conductivity.

■ Good electrical insulation, non-magnetic, electromagnetic.

■ Resistance to corrosion, rotting and warping.

■ No rust

■ Chemical resistance (potash environment, hydrochloric acid, alkali, sea water and other aggressive environments).

■ Easy handling and transportation.

■ High economic

Basalt fiber rebar can replace steel rebar or carbon fiber rebar in some industrial application and in some special complex environments.

Product Application

Due to its performance, now the basalt fiber rebar is widely used into:

■ Concrete reinforcement.

■ Road reinforcement.

■ Marine engineering.

■ Tunnel engineering.

■ Magnetic resonance imaging rooms for health care

■ Military facilities.

Concrete infrastructural

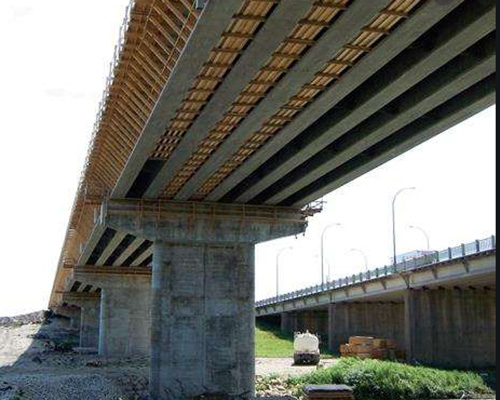

Bridge

Tunnel

Roads

Concrete construction products

Dyke-dam reinforcement

Product Specification

4mm, 6mm, 8mm, 10mm, 12.7mm, 14mm, 16mm, 18mm, 22mm, 32mm are common and popular size, we accept customized.

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Manufacturing Companies for Basalt Insulation Sleeving - Basalt fiber rebar – Huabin, The product will supply to all over the world, such as: Egypt, Rwanda, Cape Town, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.