Basalt direct roving

Product Profile

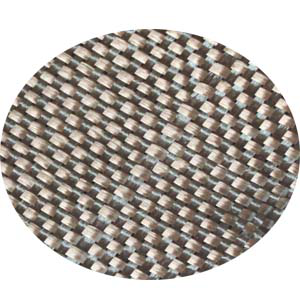

Basalt direct roving

Basalt assembled roving

Basalt direct roving is a continuous single-end strand produced pass through the bushing.

Basalt assembled roving consist of several single-end strand assembled together by special assembled machine.

Basalt direct roving can directly used in some industrial application, like textiles fabric, geogrid, woven thermal insulation tape/rope or pultrusion field. But some industrial application asks higher tex and external unwinding, that’s need basalt assembled roving.

Comparing to E-glass fiber and S-glass fiber, or even carbon fiber, basalt fiber has more natural performance advantages:

Thermophysical Properties

| Using temperature / ℃ | -260 – 700 |

| Sintering temperature / ℃ | 1050 |

| Thermal conductivity / W/m.k | 0.03 – 0.038 |

| Strength retention after heat treatment |

|

| 20℃ | 100 |

| 200℃ | 95 |

| 400℃ | 82 |

Chemical Properties – Weightlessness

| 3-hour boiling in 2N HC1 | 2.20% |

| 3-hour boiling in 2N NaOH | 6.00% |

| 3-hour boiling in H2O | 0.20% |

Moreover, basalt fiber roving has excellent mechanical and chemical performance as following technical:

■ High frost temperature resistance, high temperature resistance

■ Excellent thermal insulation

■ Corrosion and chemical resistance to alkali and resistance to salty sea water

■ Sound adsorption

■ Electric insulation

■ High tension strength and stiffness

■ Environmental friendly to soil, air and human

Product Application

In view of its excellent performance, basalt fiber roving can use in various fields:

Spray application

Pultrusion bar

Geogrid production

Basalt fabric

Pultrusion profiles

Car parts

High pressure vessel (winding)

Product Specification

|

Monofilament diameter / um |

9-24 |

|

Linear density / tex |

200-4800 |

|

Sizing type |

Silane base |

|

Sizing content / % |

≥0.4 |

|

Moisture content / % |

≤0.2 |

|

Resin compatibility |

Epoxy, vinyl ester, polyester resin, PP, PE, PA |